Aluminium Machining in China

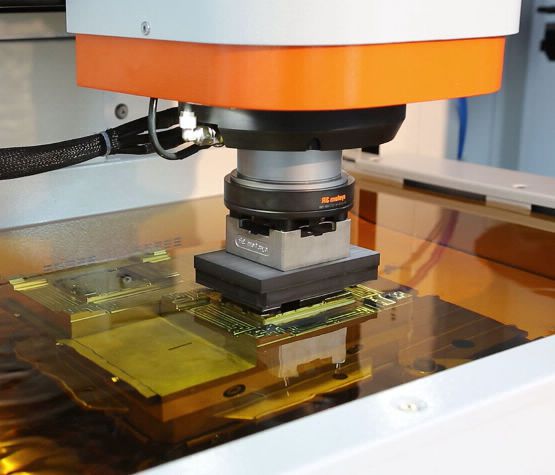

As one leading CNC aluminium machining China company, our high precision milling capabilities cover full range of requirements, including horizontal milling, vertical milling, high speed milling, bridgeport milling, 5 axis milling, custom aluminium milling, 3/4 axis CNC milling, etc.

CNC milling process is an efficient way to cut material in 3 to 5 dimensions to make the intended part shape. Due to its good capabilities and great efficiency, precision milling has been the most famous precise machining service all over the world for more than 20 years.