Precision Machining Services

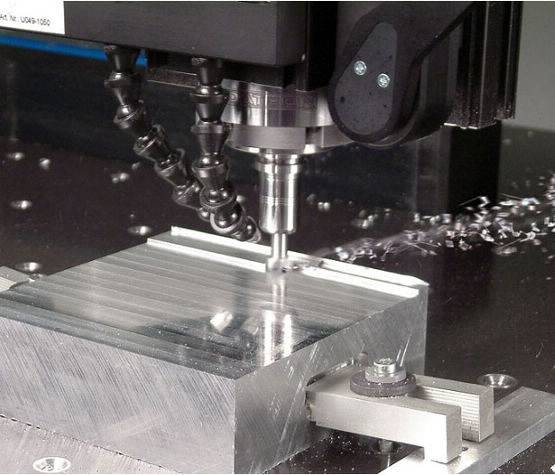

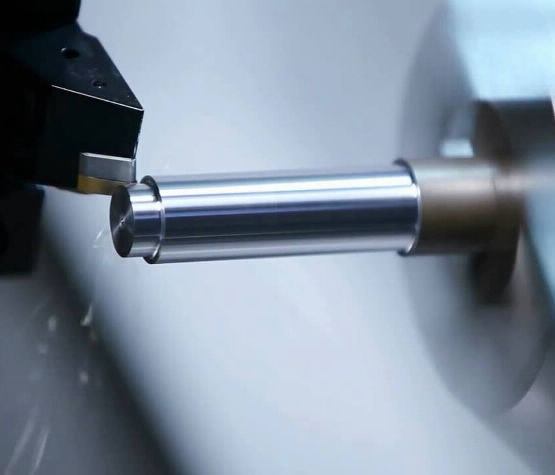

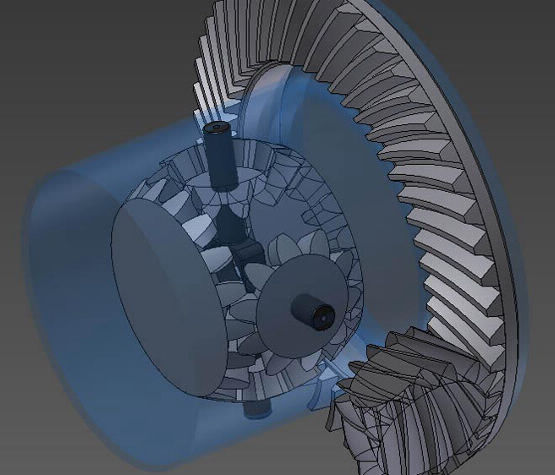

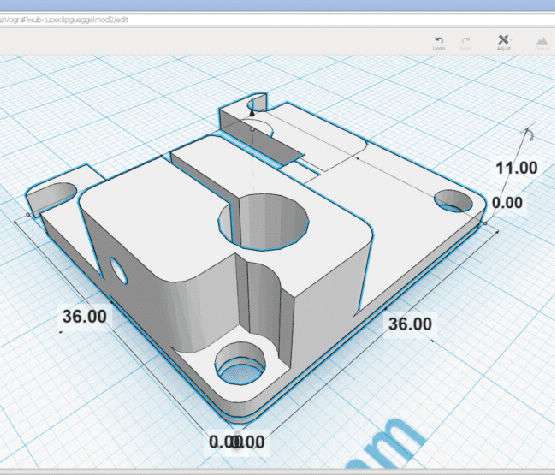

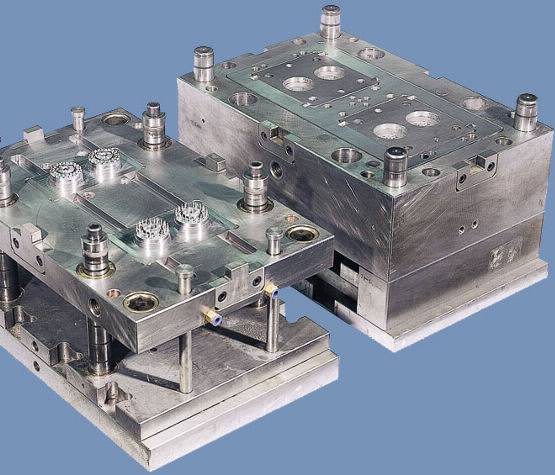

Being a CNC precision machining services Chinese supplier for various practices across many industries, we offer diverse precise machining processes, which include CNC turning, CNC milling, precision grinding and quality tapping, EDM wire cut also accurate laser cutting.

Sinker EDM and wire EDM cutting have been playing a very important role in machining industry to attain tight tolerance, specially for parts and products in small quantity but with requirements of tiny slots in high dimension tolerance and fine finish of surface.