Verify out these precision cutting pictures:

The utmost precision is necessary of these operators who are cutting and drilling parachute packs in an eastern factory, Manchester, Conn. Their function is below constant close supervision. Pioneer Parchute Company (LOC)

Image by The Library of Congress

Rittase, William M.,, 1894-1968,, photographer.

The utmost precision is necessary of these operators who are cutting and drilling parachute packs in an eastern factory, Manchester, Conn. Their function is below constant close supervision. Pioneer Parchute Firm

1942 Aug.

1 transparency : color.

Notes:

Title from FSA or OWI agency caption.

Transfer from U.S. Workplace of War Data, 1944.

Subjects:

Pioneer Parachute Business

Parachute business

World War, 1939-1945

United States–Connecticut–Manchester

Format: Transparencies–Colour

Rights Info: No recognized restrictions on publication.

Repository: Library of Congress, Prints and Photographs Division, Washington, D.C. 20540 USA, hdl.loc.gov/loc.pnp/pp.print

Part Of: Farm Safety Administration – Office of War Details Collection 12002-52 (DLC) 93845501

General info about the FSA/OWI Colour Photographs is offered at hdl.loc.gov/loc.pnp/pp.fsac

Higher resolution image is obtainable (Persistent URL): hdl.loc.gov/loc.pnp/fsac.1a35383

Get in touch with Number: LC-USW36-279

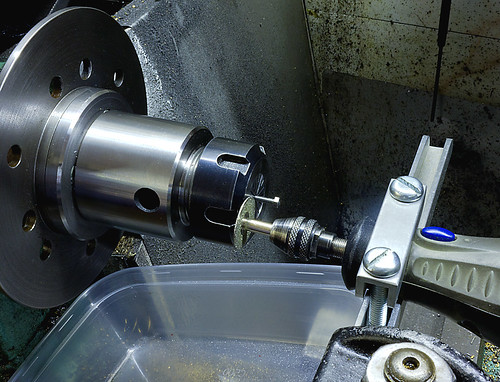

Cutting 7BA Machine Screws To length

Image by tudedude

Making use of a high speed Dremel mounted on the lathe to reduce Machine Screws to size.

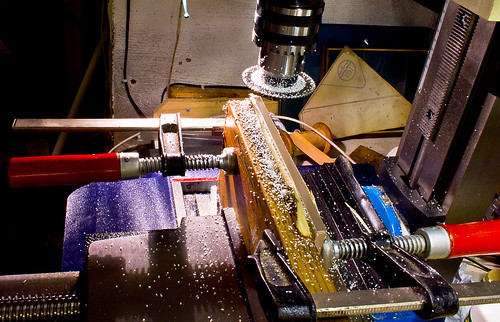

Cutting Perspex

Image by tudedude

Assistance the material cut with wood supports, Set the material and blade to reduce toward the backing.

For thin material location the wooden backing so that the blade actually cuts into the backing slighly. Use quite slow cutting speeds.