Some cool machined elements makers photos:

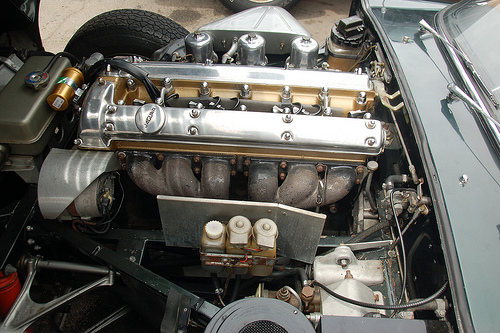

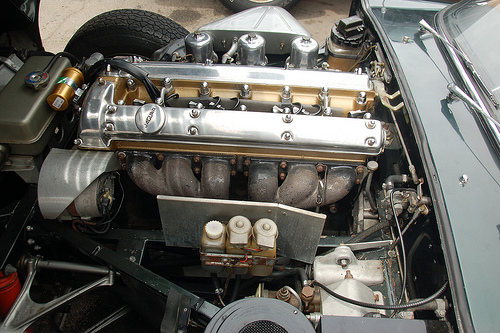

Jaguar E-Kind four.2 at Samuel’s in Allston: Engine view

Image by Chris Devers

Quoting from Wikipedia: Jaguar E-Sort:

• • • • •

The Jaguar E-Variety (UK) or XK-E (US) is a British automobile manufactured by Jaguar amongst 1961 and 1974. Its combination of very good looks, higher functionality, and competitive pricing established the marque as an icon of 1960s motoring. A fantastic achievement for Jaguar, over seventy thousand E-Varieties were sold in the course of its lifespan.

In March 2008, the Jaguar E-Kind ranked very first in Everyday Telegraph list of the "100 most stunning cars" of all time.[2] In 2004, Sports Vehicle International magazine placed the E-Sort at number a single on their list of Leading Sports Cars of the 1960s.

Contents

• 1 Overview

• two Idea versions

•• two.1 E1A (1957)

•• two.two E2A (1960)

• three Production versions

•• three.1 Series 1 (1961-1968)

•• 3.2 Series two (1969-1971)

•• three.three Series three (1971-1975)

• 4 Limited edtions

•• 4.1 Low Drag Coupé (1962)

•• four.2 Lightweight E-Sort (1963-1964)

• five Motor Sport

• 6 See also

• 7 References

• 8 External hyperlinks

Overview

The E-Variety was initially made and shown to the public as a grand tourer in two-seater coupé type (FHC or Fixed Head Coupé) and as convertible (OTS or Open Two Seater). The two+two version with a lengthened wheelbase was released many years later.

On its release Enzo Ferrari referred to as it "The most beautiful automobile ever produced".

The model was made in three distinct versions which are now usually referred to as "Series 1", "Series two" and "Series three". A transitional series among Series 1 and Series 2 is identified unofficially as "Series 1½".

In addition, several limited-edition variants have been created:

• The "’Lightweight’ E-Variety" which was apparently intended as a sort of comply with-up to the D-Variety. Jaguar planned to generate 18 units but eventually only a dozen have been reportedly constructed. Of those, one particular is recognized to have been destroyed and two other people have been converted to coupé kind. These are exceedingly uncommon and sought soon after by collectors.

• The "Low Drag Coupé" was a a single-off technical physical exercise which was in the end sold to a Jaguar racing driver. It is presently believed to be element of the private collection of the existing Viscount Cowdray.

Concept versions

E1A (1957)

Following their good results at LeMans 24 hr via the 1950s Jaguars defunct racing department had been provided the brief to use D-Sort style building to create a road going sports vehicle, replacing the XK150.

It is suspected that the first prototype (E1A) was given the code based on: (E): The proposed production name E-Sort (1): First Prototype (A): Aluminium building (Production models employed steel bodies)

The automobile featured a monocoque design and style, Jaguar’s totally independent rear suspension and the properly proved "XK" engine.

The automobile was utilized solely for factory testings and was never ever formally released to the public. The automobile was ultimately scrapped by the factory

E2A (1960)

Jaguar’s second E-Sort notion was E2A which as opposed to E1A was constructed from a steel chassis and utilized a aluminium body. This auto was completed as a race auto as it was believed by Jaguar at the time it would supply a far better testing ground.

E2A utilized a three litre version of the XK engine with a Lucas fuel injection method.

Right after retiring from the LeMans 24 hr the auto was shipped to America to be employed for racing by Jaguar privateer Briggs Cunningham.

In 1961 the auto returned to Jaguar in England to be utilized as a testing mule.

Ownership of E2A passed to Roger Woodley (Jaguars buyer competition car manager) who took possession on the basis the auto not be utilized for racing. E2A had been scheduled to be scrapped.

Roger’s wife Penny Griffiths owned E2A till 2008 when it was presented for sale at Bonham’s Quail Auction. Sale value was US.five million

Production versions

Series 1 (1961-1968)

Series I

• Production

1961–1968[three] [four]

• Body style(s)

two-door coupe

2-door 2+2 coupe

2-door convertible

• Engine(s)

3.8 L XK I6

four.two L XK I6

• Wheelbase

96. in (2438 mm) (FHC / OTS)

105. in (2667 mm) (2+2) [5]

• Length

175.3125 in (4453 mm) (FHC / OTS)

184.4375 in (4685 mm) (2+2) [five]

• Width

65.25 in (1657 mm) (all) [5]

• Height

48.125 in (1222 mm) (FHC)

50.125 in (1273 mm) (two+two)

46.5 in (1181 mm) (OTS)[5]

• Curb weight

two,900 lb (1,315 kg) (FHC)

2,770 lb (1,256 kg) (OTS)

3,090 lb (1,402 kg) (two+2) [six]

• Fuel capacity

63.64 L (16.eight US gal 14. imp gal)[five]

The Series 1 was introduced, initially for export only, in March 1961. The domestic marketplace launch came four months later in July 1961.[7] The cars at this time used the triple SU carburetted three.8 litre six-cylinder Jaguar XK6 engine from the XK150S. The initial 500 cars constructed had flat floors and external hood (bonnet) latches. These vehicles are uncommon and a lot more valuable. After that, the floors were dished to offer much more leg space and the twin hood latches moved to inside the vehicle. The three.eight litre engine was elevated to four.two litres in October 1964.[7]

All E-Varieties featured independent coil spring rear suspension with torsion bar front ends, and four wheel disc brakes, in-board at the rear, all have been power-assisted. Jaguar was one of the 1st auto manufacturers to equip cars with disc brakes as regular from the XK150 in 1958. The Series 1 can be recognised by glass covered headlights (up to 1967), modest "mouth" opening at the front, signal lights and tail-lights above bumpers and exhaust ideas beneath the licence plate in the rear.

3.eight litre automobiles have leather-upholstered bucket seats, an aluminium-trimmed centre instrument panel and console (changed to vinyl and leather in 1963), and a Moss 4-speed gearbox that lacks synchromesh for 1st gear ("Moss box"). four.two litre automobiles have more comfy seats, enhanced brakes and electrical systems, and an all-synchromesh four-speed gearbox. four.two litre automobiles also have a badge on the boot proclaiming "Jaguar four.2 Litre E-Type" (3.8 cars have a easy "Jaguar" badge). Optional extras incorporated chrome spoked wheels and a detachable challenging leading for the OTS.

An original E-Sort challenging best is quite uncommon, and discovering 1 intact with all the chrome, not to mention original paint in decent situation, is rather challenging. For those who want a hardtop and aren’t fussy more than whether or not it is an original from Jaguar, many third parties have recreated the hardtop to almost exact specifications. The price ranges anywhere from double to triple the cost of a canvas/vinyl soft leading.

A two+2 version of the coupé was added in 1966. The two+two provided the selection of an automatic transmission. The physique is 9 in (229 mm) longer and the roof angles are distinct with a more vertical windscreen. The roadster remained a strict two-seater.

There was a transitional series of automobiles constructed in 1967-68, unofficially referred to as "Series 1½", which are externally comparable to Series 1 cars. Due to American stress the new characteristics have been open headlights, different switches, and some de-tuning (with a downgrade of twin Zenith-Stromberg carbs from the original triple SU carbs) for US models. Some Series 1½ vehicles also have twin cooling fans and adjustable seat backs. Series 2 features were steadily introduced into the Series 1, creating the unofficial Series 1½ cars, but constantly with the Series 1 physique style.

Less broadly identified, there was also appropriate at the finish of Series 1 production and prior to the transitional "Series 1½" referred to above, a very modest quantity of Series 1 cars created with open headlights.[8] These are often referred to as "Series 1¼" cars.[9] Production dates on these machines vary but in right hand drive type production has been verified as late as March 1968.[ten] It is thought that the low quantity of these vehicles created relative to the other Series make them amongst the rarest of all production E Types.

An open three.8 litre automobile, actually the very first such production auto to be completed, was tested by the British magazine The Motor in 1961 and had a leading speed of 149.1 mph (240. km/h) and could accelerate from -60 mph (97 km/h) in 7.1 seconds. A fuel consumption of 21.3 miles per imperial gallon (13.3 L/100 km 17.7 mpg-US) was recorded. The test car cost £2097 including taxes.[11]

Production numbers from Graham[12]:

• 15,490 3.8s

• 17,320 four.2s

• 10,930 2+2s

Production numbers from xkedata.com[13]: [omitted — Flickr doesn’t allow tables]

Series two (1969-1971)

Series II

• Production

1969–1971[three] [4]

• Body style(s)

2-door coupe

2-door 2+2 coupe

two-door convertible

• Engine(s)

4.two L XK I6

• Curb weight

3,018 lb (1,369 kg) (FHC)

two,750 lb (1,247 kg) (OTS)

three,090 lb (1,402 kg) (2+two) [6]

Open headlights with out glass covers, a wrap-about rear bumper, re-positioned and bigger front indicators and taillights below the bumpers, much better cooling aided by an enlarged "mouth" and twin electric fans, and uprated brakes are hallmarks of Series 2 cars. De-tuned in US, but nevertheless with triple SUs in the UK, the engine is very easily identified visually by the adjust from smooth polished cam covers to a more industrial ‘ribbed’ look. Late Series 1½ automobiles also had ribbed cam covers. The interior and dashboard were also redesigned, with rocker switches that met U.S well being and safety regulations getting substituted for toggle switches. The dashboard switches also lost their symmetrical layout. New seats were fitted, which purists claim lacked the style of the originals but were certainly far more comfortable. Air conditioning and energy steering were accessible as factory possibilities.

Production according to Graham[12] is 13,490 of all sorts.

Series two production numbers from xkedata.com[13]: [omitted — Flickr doesn’t let tables]

Official delivery numbers by industry and year are listed in Porter[three] but no summary totals are provided.

Series 3 (1971-1975)

Series III

• Production

1971–1975

• Physique style(s)

two-door 2+two coupe

two-door convertible

• Engine(s)

five.3 L Jaguar V12

• Wheelbase

105 in (2667 mm) (both)[six]

• Length

184.four in (4684 mm) (two+2)

184.5 in (4686 mm) (OTS)[6]

• Width

66. in (1676 mm) (two+2)

66.1 in (1679 mm) (OTS)[six]

• Height

48.9 in (1242 mm) (two+two)

48.1 in (1222 mm) (OTS)[6]

• Curb weight

3,361 lb (1,525 kg) (2+2)

3,380 lb (1,533 kg) (OTS)[6]

• Fuel capacity

82 L (21.7 US gal 18. imp gal)[14]

A new 5.three L 12-cylinder Jaguar V12 engine was introduced, with uprated brakes and common power steering. The short wheelbase FHC body style was discontinued and the V12 was accessible only as a convertible and two+two coupé. The convertible utilized the longer-wheelbase two+two floorplan. It is very easily identifiable by the large cross-slatted front grille, flared wheel arches and a badge on the rear that proclaims it to be a V12. There were also a quite limited number of 4.two litre six-cylinder Series 3 E-Kinds constructed. These were featured in the initial sales literature. It is believed these are the rarest of all E-Types of any remaining.

In 2008 a British classic vehicle enthusiast assembled what is certainly the last ever E-Type from components bought from the finish-of-production surplus in 1974.[15]

Graham[12] lists production at 15,290.

Series 3 production numbers from xkedata.com[13]: [omitted — Flickr does not enable tables]

Restricted edtions

Two restricted production E-Sort variants have been produced as test beds, the Low Drag Coupe and Lightweight E-Variety, each of which have been raced:

Low Drag Coupé (1962)

Shortly soon after the introduction of the E-Sort, Jaguar management wanted to investigate the possibility of constructing a auto a lot more in the spirit of the D-Kind racer from which components of the E-Type’s styling and style had been derived. 1 vehicle was built to test the concept designed as a coupé as its monocoque design and style could only be created rigid enough for racing by using the "stressed skin" principle. Prior Jaguar racers were built as open-top vehicles due to the fact they had been based on ladder frame styles with independent chassis and bodies. Unlike the steel production E-Kinds the LDC used lightweight aluminium. Sayer retained the original tub with lighter outer panels riveted and glued to it. The front steel sub frame remained intact, the windshield was provided a much more pronounced slope and the rear hatch welded shut. Rear brake cooling ducts appeared subsequent to the rear windows,and the interior trim was discarded, with only insulation about the transmission tunnel. With the exception of the windscreen, all cockpit glass was plexi. A tuned version of Jaguar’s 3.eight litre engine with a wide angle cylinder-head design and style tested on the D-Sort racers was used. Air management became a significant problem and, even though significantly sexier looking and undoubtedly faster than a production E-Variety, the automobile was by no means competitive: the more quickly it went, the far more it wanted to do what its style dictated: take off.

The one particular and only test bed automobile was completed in summer season of 1962 but was sold a year later to Jaguar racing driver Dick Protheroe who raced it extensively and ultimately sold it. Considering that then it has passed by means of the hands of a number of collectors on each sides of the Atlantic and now is believed to reside in the private collection of the existing Viscount Cowdray.

Lightweight E-Sort (1963-1964)

In some ways, this was an evolution of the Low Drag Coupé. It made in depth use of aluminium alloy in the body panels and other components. Nevertheless, with at least 1 exception, it remained an open-leading car in the spirit of the D-Type to which this vehicle is a much more direct successor than the production E-Sort which is more of a GT than a sports automobile. The vehicles utilised a tuned version of the production three.eight litre Jaguar engine with 300 bhp (224 kW) output rather than the 265 bhp (198 kW) created by the "ordinary" version. At least one particular car is recognized to have been fitted with fuel-injection.

The vehicles had been entered in various races but, as opposed to the C-Kind and D-Sort racing automobiles, they did not win at Le Mans or Sebring.

Motor Sport

Bob Jane won the 1963 Australian GT Championship at the wheel of an E-Kind.

The Jaguar E-Sort was really successful in SCCA Production sports auto racing with Group44 and Bob Tullius taking the B-Production championship with a Series-3 V12 racer in 1975. A couple of years later, Gran-Turismo Jaguar from Cleveland Ohio campaigned a four.two L 6 cylinder FHC racer in SCCA production series and in 1980, won the National Championship in the SCCA C-Production Class defeating a fully funded factory Nissan Z-car group with Paul Newman.

See also

• Jaguar XK150 – predecessor to the E-Variety

• Jaguar XJS – successor to the E-Sort

• Jaguar XK8 – The E-Type’s existing and spiritual successor

• Guyson E12 – a rebodied series III constructed by William Towns

References

• ^ Loughborough graduate and designer of E Kind Jaguar honoured

• ^ 100 most gorgeous vehicles

• ^ a b cPorter, Philip (2006). Jaguar E-variety, the definitive history. p. 443. ISBN -85429-580-1.

• ^ a b"’69 Series two Jaguar E Types", Autocar, October 24, 1968

• ^ a b c d eThe Full Official Jaguar "E". Cambridge: Robert Bentley. 1974. p. 12. ISBN -8376-0136-3.

• ^ a b c d e f g"Jaguar E-Sort Specifications". http://www.web-cars.com/e-sort/specifications.php. Retrieved 29 August 2009.

• ^ a b"Buying secondhand E-type Jaguar". Autocar 141 (nbr4042): pages 50–52. 6 April 1974.

• ^ See Jaguar Clubs of North America concourse info at: [1] and more specifically the actual Series 1½ concourse guide at [two]

• ^ Ibid.

• ^ Examine proper hand drive VIN numbers given in JCNA concours guide referred to above with production dates for appropriate hand drive vehicles as reflected in the XKEdata database at [three]

• ^"The Jaguar E-kind". The Motor. March 22, 1961.

• ^ a b cRobson, Graham (2006). A–Z British Vehicles 1945–1980. Devon, UK: Herridge & Sons. ISBN -9541063-9-3.

• ^ a b chttp://www.xkedata.com/stats/. http://www.xkedata.com/stats/. Retrieved 29 August 2009.

• ^Every day Express Motor Show Assessment 1975 Automobiles: Page 24 (Jaguar E V12). October 1974.

• ^ jalopnik.com/5101872/british-man-cobbles-with each other-last-ja…

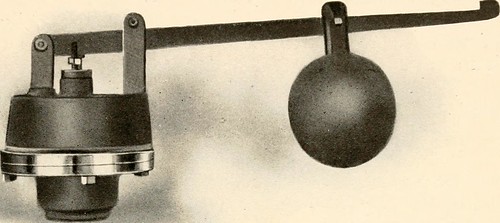

Imperial Performs, Menston

Image by tj.blackwell

G.L Murphy Machinery Ltd. was an industrial components manufacturer established in 1930. They had been primarily based in this mill, named Imperial Performs, on the rural outskirts of Menston in West Yorkshire. The business produced tools, belt driven machinery, transmissions and electrical equipment, specialising in products for tanners and leather companies in addition to glue and gelatine plants. They created batch runs of specialist components and carried out renovation function on a variety of machine components.

Imperial Works is primarily constructed from locally mined millstone grit and characteristics an desirable redbrick chimney. It covers a pretty expansive location amid rural farmland to the north of Menston, just off Otley Road. Some components of the site are nevertheless in use but this older section is now falling into fast decay. Most clues from items identified inside the G.L Murphy factory appear to date its closure to the 1970s.

Click here to view the rest of the image set for a tour inside the decaying old mill.