Check out these rapid prototype machining images:

Steven F. Udvar-Hazy Center: Grumman F6F-3 Hellcat

Image by Chris Devers

Quoting Smithsonian National Air and Space Museum | Grumman F6F-3 Hellcat:

The Grumman F6F Hellcat was originally conceived as an advanced version of the U.S. Navy’s then current front-line fighter, the F4F Wildcat (see NASM collection). The Wildcat’s intended replacement, the Vought F4U Corsair (see NASM collection), first flown in 1940, was showing great promise, but development was slowed by problems, including the crash of the prototype.

The National Air and Space Museum’s F6F-3 Hellcat, BuNo. 41834, was built at Grumman’s Bethpage, New York, factory in February 1944 under contract NOA-(S)846. It was delivered to the Navy on February 7, and arrived in San Diego, California, on the 18th. It was assigned to Fighter Squadron 15 (VF-15) on USS Hornet (CV12) bound for Hawaii. On arrival, it was assigned to VF-3 where it sustained damage in a wheels-up landing at NAS Barbers Point, Hawaii. After repair, it was assigned to VF-83 where it was used in a training role until February 21, 1945. After numerous transfers 41834 was converted to an F6F-3K target drone with the installation of sophisticated radio-control equipment. It was painted red with a pink tail that carried the number 14. Its mission was to be used in Operation Crossroads – the atomic bomb tests at Bikini Atoll. It flew on June 24, 1946, with a pilot, on a practice flight and was launched, unmanned, soon after the first bomb test. Instrumentation on board and photographic plates taped to the control stick obtained data on radioactivity. Three more manned flights preceded the final unmanned flight on July 25, 1946, which evaluated the first underwater explosion. Records indicate that exposure of this aircraft to the radioactive cloud was minimal and residual radiation is negligible.

F6F-3K 41834 was transferred to NAS Norfolk and logged its last flight on March 25, 1947, with a total of 430.2 flying hours. It was assigned to the National Air Museum on November 3, 1948, and remained at Norfolk until October 4, 1960, when it was moved by barge to Washington and placed in storage. In 1976 this Hellcat was loaned to the USS Yorktown Museum at Charleston, South Carolina. A superficial restoration was performed at the museum, but because of the harsh environment and its poor condition the Hellcat was returned to NASM on March 16, 1982. In 1983, it was sent to Grumman Aerospace where a team of volunteers completely restored the aircraft. In 1985, it was shipped back to the Paul E. Garber Preservation, Restoration and Storage Facility in Suitland, Maryland, and put in storage. NASM’s F6F-3 Hellcat is scheduled to be displayed in the new Steven F. Udvar-Hazy center at Dulles International Airport in Virginia in 2004.

Transferred from the United States Navy.

Manufacturer:

Grumman Aircraft China Engineering Corporation

Date:

1943

Country of Origin:

United States of America

Dimensions:

Overall: 338 x 1021cm, 4092kg, 1304cm (11ft 1 1/16in. x 33ft 5 15/16in., 9021.2lb., 42ft 9 3/8in.)

Physical Description:

Heavy armor plate, reinforced empennage, R-2800-10W engine, spring tabs on the ailerons (increased maneuverability), could carry rockets as well as bombs.

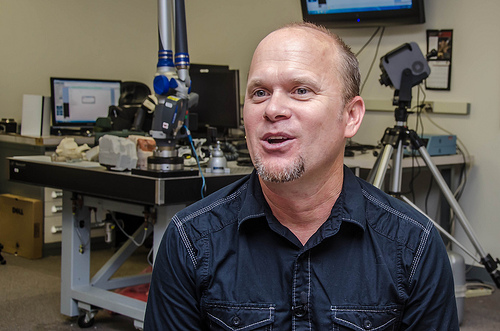

Army researchers use 3D printers for rapid prototypes

Image by RDECOM

ABERDEEN PROVING GROUND, Md. — When you walk into this research lab you hear the overpowering hum of massive machines with robotic parts swinging past viewing windows as technicians spray objects with lasers attached to limber metallic arms.

Fifty years ago what goes on in this lab would have been considered science fiction, but what these Army researchers do is scientific fact.

These artisan engineers create three-dimensional objects out of plastic and metal in printers that seem more like Star Trek replicators.

Read more at go.usa.gov/YTEw