Image from page 376 of “Railway mechanical engineer” (1916)

Image by World wide web Archive Book Photos

Identifier: railwaymechanica93newy

Title: Railway mechanical engineer

Year: 1916 (1910s)

Authors:

Subjects: Railroad engineering Engineering Railroads Railroad automobiles

Publisher: New York, N.Y. : Simmons-Boardman Pub. Co

View Book Web page: Book Viewer

About This Book: Catalog Entry

View All Pictures: All Images From Book

Click here to view book on the web to see this illustration in context in a browseable on the internet version of this book.

Text Appearing Just before Image:

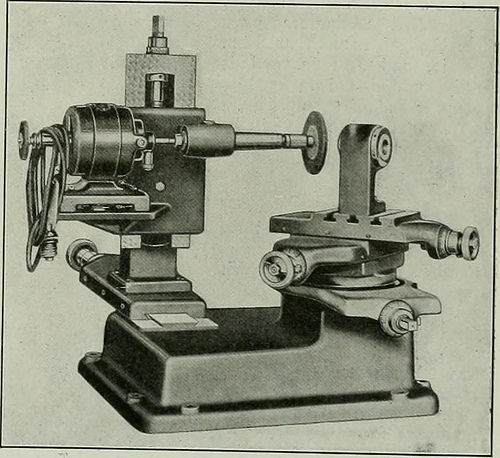

ustablebronze bearings and carries a wheel 4 in. in diameter, 54in., face with a ^-in. hole. The bracket carrying the motorand wheel spindle is mounted on a vertical housing and isadjusted by a screw provided with a micrometer dial. Arbors for holding the perform are held in a sleeve whichrevolves freely in the operate holding posts. 4 posts arefurnished with No. 9 and No. 7 Brown & Sharpe tapers,1 with a J/2-in. straight hole and a single flat block for hold-ing flat tools, in order to cover all classes of work capableof getting accomplished on the machine. The posts match into 3 T-slots in the upper compound slide, therefore offering for awide range of function. The two upper slides are employed tobring the perform in the proper sweep across the face of thewheel, and are in turn mounted on a swivel block, which ispivoted to the bottom slide. The maximum radius that can be ground is three in. oneither concave or convex cutters up to 12 in. in diameter.A gage is furnished to set the operate in the suitable relation to

Text Appearing After Image:

Motor Driven Profile Grinder the wheel and when the slide is set for any offered radius themachine will always grind that radius regardless of the con-tinued adjustment of the two upper slides. A simple and jdS RAILWAY MECHANICAL EXGIXEER nL. 93, No. six hassle-free tooth rest is furnished with range enough to cover are accurately scraped and provided with gibs for taking upall function within the capacity of the machine. All scews the wear. The machine occupies a bench space of 24 in.are offered with readable micrometer dials and the slides by .50 in. and weighs 217 lb. A Higher Energy Numerous SPINDLE DRILL THE numerous spindle drill shown in the illustrationis a heavy service production tool specially intendedfor use in locomotive and railway shops and willbe identified helpful exactly where the work includes heavy gang drillingor heavy jig drilling. When utilised on jig perform tlie compact-ness of this drill enables 1 operator to hold a greaternumber of spindles—either singly or in groups—continuallyin

Note About Pictures

Please note that these pictures are extracted from scanned page photos that may have been digitally enhanced for readability – coloration and look of these illustrations may possibly not completely resemble the original function.

Hardinge Inc. to Present at the 2014 Western New York Investors Conference

Hardinge applies its engineering design and manufacturing expertise in high overall performance machining centers, high-end cylindrical and jig grinding machines, SUPER-PRECISION® and precision CNC lathes and technologically advanced workholding …

Read much more on Stockhouse

Peter Marigold on Demonic Voices, Porridge Addiction, and the Worth of Blind …

Apart from that, it's probably endlessly trawling through woodworking internet sites, hunting for exciting techniques and jigs. That's a terrible, terrible habit. … I think the planet is grinding to a halt because of computers. I meet a lot of young …

Read much more on Core77.com (blog)

Why Producers Need to Worry 3D Printing

In most circumstances, the business wants to undergo forging, grinding, milling and assembly. All of this is after the molds, jigs and fixtures required have been produced and perfected. With 3D printing, an finish-use item can be created all in a single step. It is …

Study a lot more on Benzinga