Check out these blanchard China grinding services images:

Image from page 389 of “Fitchburg, Massachusetts, past and present” (1887)

Image by Internet Archive Book Images

Identifier: fitchburgmassach00inemer

Title: Fitchburg, Massachusetts, past and present

Year: 1887 (1880s)

Authors: Emerson, William A. (William Andrew), 1851- 4n

Subjects:

Publisher: Fitchburg : Press of Blanchard & Brown

View Book Page: Book Viewer

About This Book: Catalog Entry

View All Images: All Images From Book

Click here to view book online to see this illustration in context in a browseable online version of this book.

Text Appearing Before Image:

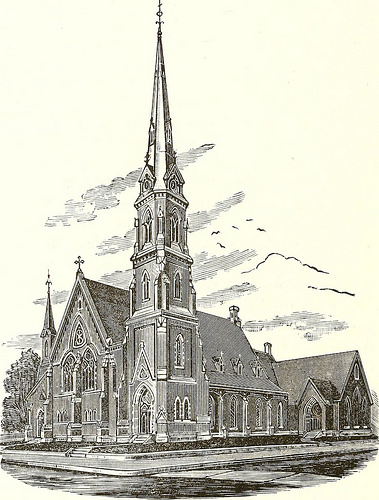

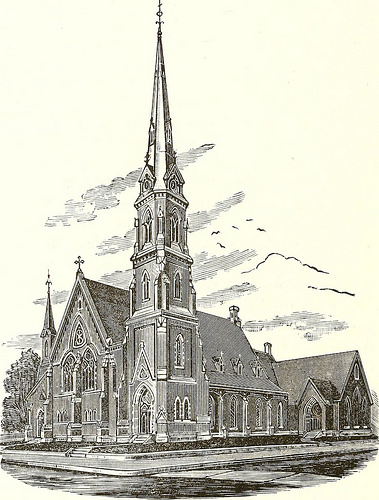

held in the church. Charles Morris Addison, the present Rector of Christchurch, was born in Charlestown, Mass., July 16, 1856.His early life was passed in Washington, D. C, where hewas educated at the Preparatory Department of ColumbiaCollege. He was prepared by tutor for the RensselaerPolytechnic Institute at Troy, N. Y., where he studied civilengineering. In 1878 he went to Cambridge, Mass., andprepared at Harvard College and the Episcopal TheologicalSchool for the ministry. Graduating in 1882, he was calledto the Rectorship of St. Johns church, Arlington, Mass., andappointed missionary at Winchester. In 1885 he was calledto his present parish and assumed charge June 1, 1885. 302 FITCHBURG, PAST AND PRESENT. ROLLSTONE CONGREGATIONAL CHURCH. In 1868, owing to the insufficiency of the Calvinisticchurch to accommodate the increased congregations, and theevident need of a church in the easterly section of the village,a division took place, and the Rollstone church and societywas formed.

Text Appearing After Image:

ROLLSTONE CONGREGATIONAL CHURCH. Rev. Leverett W. Spring, a graduate of Williams Col-lege and of Hartford Theological Seminary was engaged aspastoral supply for one year. The first public services wereheld in the hall of the American House, March 8, 1868. CHURCHES AND HOMES. .><».) The church was organized on the sixteenth of the followingmonth, comprising 150 members. Oliver Ellis and J. A.Conn were appointed deacons -pro ton fore. On the sameday Mr. Spring was ordained, and installed as pastor. Soonafter this the society was incorporated, and steps were imme-diately taken to raise funds for building a church. A sitewas secured at the intersection of Main and Snow streets,ground was broken for the foundation in August, 1868, andthe corner stone laid Oct. 5, of the same year. The churchwas dedicated Feb. 24, 1870. The first deacons of thechurch were Samuel Burnap, Oliver Ellis, John A. Conn, S.Newell Weston, David Boutelle, William L. Bullock. Thepastors have been Rev. Leverett

Note About Images

Please note that these images are extracted from scanned page images that may have been digitally enhanced for readability – coloration and appearance of these illustrations may not perfectly resemble the original work.

Image from page 246 of “Fitchburg, Massachusetts, past and present” (1887)

Image by Internet Archive Book Images

Identifier: fitchburgmassach00inemer

Title: Fitchburg, Massachusetts, past and present

Year: 1887 (1880s)

Authors: Emerson, William A. (William Andrew), 1851- 4n

Subjects:

Publisher: Fitchburg : Press of Blanchard & Brown

View Book Page: Book Viewer

About This Book: Catalog Entry

View All Images: All Images From Book

Click here to view book online to see this illustration in context in a browseable online version of this book.

Text Appearing Before Image:

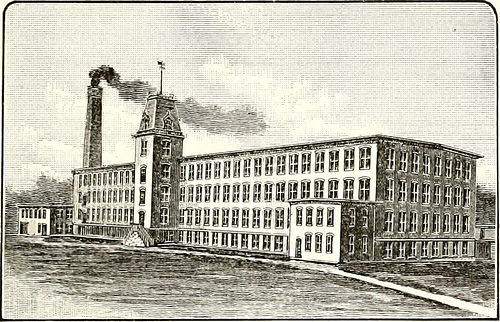

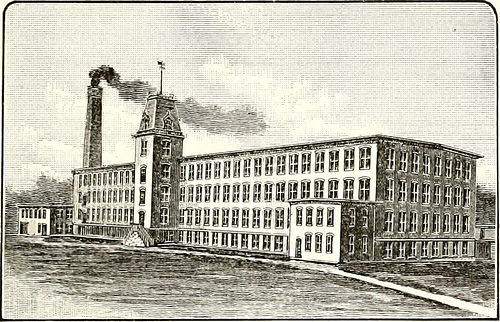

the cotton business. He was born near Glas-gow, in Scotland, came to this country and located in MANUFACTURING. 107 Adams, Mass., in 1848, where he remained until he removedto North Adams in 1862. From there he came to Fitchburg in 1885. THIi ORSWELL MILL is the latest addition to the industries of Fitchburg, its loca-tion is on River street, bordering on the Fitchburg railroad.Ground was broken for the mill May 1, 1886, and a sub-stantial brick building 346 by 78 feet, four stories, built. The product is finenumbers of cottonyarn. The capac-ity ot the mill is20,000 spindles ca-pable of producing24,000 pounds ofyarn per week.The capital is atpresent 0,000.Its officers areorswell mill. Warren M. Ors- well, president and general manager; W. F. Stiles, treas-urer. Mr. Orswell has long been engaged in the manufactureof cotton yarn elsewhere, and with his practical knowledgeof the business and executive ability has already made theOrswell mill one of the leading industries of Fitchburg.

Text Appearing After Image:

THE FITCHBURG COTTON MILL, located on Main street, better known as the Pitts Mill, isused for the manufacture of cotton and carpet warps, batting,twine, etc. This enterprise was founded in 1867 by Mr. H.W. Pitts, who, on the fourth of February, 1882, was suc-ceeded by his son, the present proprietor, Mr. B. MarshallPitts. The plant comprises five buildings, the main one being afour story brick structure 50 by 100 feet in dimensions.The machinery is operated by water power, and an engine 198 FITCHBURG, PAST AND PRESENT. and boilers, each of one hundred horse power, are broughtinto service when the water supply proves deficient. Themill has a capacity for producing sixty thousand pounds ofwarp per month and ninety hands are needed to carry on theoperations of the concern. THE FITCHBURG DUCK MILL, near Water street, South Fitchburg, is engaged in the manu-facture of cotton duck. The mill is owned by DavidNevins. Samuel Clough is treasurer, and Thomas H. Clark,agent. James McTaggart, Jr.,

Note About Images

Please note that these images are extracted from scanned page images that may have been digitally enhanced for readability – coloration and appearance of these illustrations may not perfectly resemble the original work.