Check out these turning manufacturing pictures:

Image from web page 421 of “Railway mechanical engineer” (1916)

Image by Net Archive Book Images

Identifier: railwaymechanica89newy

Title: Railway mechanical engineer

Year: 1916 (1910s)

Authors:

Subjects: Railroad engineering Engineering Railroads Railroad vehicles

Publisher: New York, N.Y. : Simmons-Boardman Pub. Co

Contributing Library: Carnegie Library of Pittsburgh

Digitizing Sponsor: Lyrasis Members and Sloan Foundation

View Book Page: Book Viewer

About This Book: Catalog Entry

View All Images: All Pictures From Book

Click right here to view book on-line to see this illustration in context in a browseable on the web version of this book.

Text Appearing Just before Image:

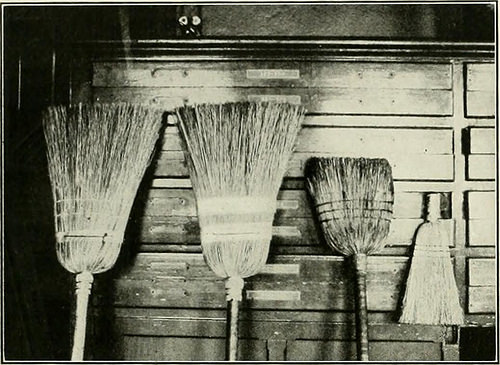

ne sewed. The bandis squeezed into location in the sewing press and an eightpennynail driven by way of it into the handle. It is then sewed withNo. 12 gauge wire, passing by way of the band and the corn asshown in the illustration. The engine broom shown at B isespecially developed to meet the needs of the additional heavyservice to which it is subjected. It is offered with two steelbands and no twine sewing is employed a bamboo insert is wovenin with the corn when binding. This has confirmed a really service-in a position adjunct. The switch broom is shown at C. Brooms of thistype arc made from reclaimed material returned to the .shop,the worn end of the corn becoming reduce off. This offers better ser-vice for track use than would new material. The whisk broom shown at D is manufactured quite cheaplyby saving out the finest of the corn when sorting material forthe manufacture of the other brooms. This saves purchasinga unique qualit of hi.uh priced corn sold for brooms of thiskind. OILING AIR PUMP MR CYLINDERS

Text Appearing Soon after Image:

Brooms Manufactured in the Shoreham Shops of the Soo Line Brooms are getting created at a saving of the following amountsas compared with the marketplace prices previously paid: frequent,five cents: engine, 4 cents whisk, five cents. To secure anew broom the old one have to be turned in. The handles of theold brooms are then reclaimed at a price of .50 per thousand,which is much less than one-third the price tag paid for new material.These handles are utilized in creating engine brooms. The greatestsaving is effected, even so, by the increased service obtainedfrom the brooms of our personal manufacture. Their life is ap-pro.ximately double that of the brooms previously purchased inthe market, this statement becoming based upon the lower in thenumber issued. This perform is handled straight by the shops division: oneman working on a contract basis furnishes all that are requiredby the road. The equipment necessary is inexpensive and con-sists of the following: winder, press, scrapper, drain board, tuband a cutting a

Note About Pictures

Please note that these photos are extracted from scanned web page images that might have been digitally enhanced for readability – coloration and look of these illustrations could not completely resemble the original operate.

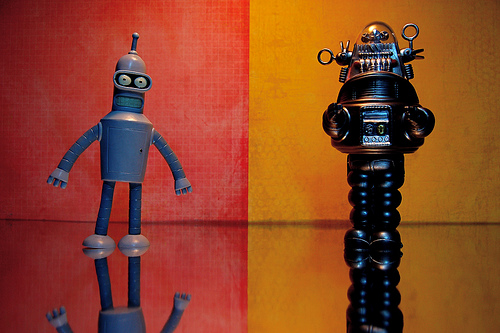

Bender vs. Robby the Robot (121/365)

Image by JD Hancock

Bender: Scheming, cynical, and oddly charming bending unit who lives in New New York at the turn of the 31st century and who is fueled by alcohol.

Robby the Robot: Careful, sturdy, and loyal assistant who lives on the plant Altair IV in the early 23rd century and who can manufacture alcohol.

If they had to fight, who would win?

#121 in the Duel 365 series.

Image from web page 270 of “The pathway of life Intended to lead the young and the old into paths of happiness, and to prepare them for a holy companionship with him whose kingdom is as boundless as his adore” (1894)

Image by Internet Archive Book Images

Identifier: pathwayoflifeint00talm

Title: The pathway of life Intended to lead the young and the old into paths of happiness, and to prepare them for a holy companionship with him whose kingdom is as boundless as his love

Year: 1894 (1890s)

Authors: Talmage, T. De Witt (Thomas De Witt), 1832-1902

Subjects: Christian life and character

Publisher: Philadelphia, Pub. and manufactured by Historical Pub. Co. for the Christian Herald

Contributing Library: Princeton Theological Seminary Library

Digitizing Sponsor: World wide web Archive

View Book Page: Book Viewer

About This Book: Catalog Entry

View All Images: All Pictures From Book

Click right here to view book on the web to see this illustration in context in a browseable online version of this book.

Text Appearing Before Image:

when we come to the stature of males in Christ Jesus, then, below these imple-ments, the temple of God will rise, and the worlds redemption will be launched.God cares not for the length of our prayers, or the quantity of our prayers, or thebeauty of our prayers, or the place of our prayers but it is the faith in them thattells—believing that prayer soars larger than the lark ever sang, plunges deeperthan diving-bell ever sank, darts faster than lightning ever flashed. Although wehave utilized only the back of this weapon as an alternative of the edge, what marvels havebeen wrought! If saved, we are all the captives of some earnest prayer. WouldGod that, in want for the rescue of souls, we may well in prayer lay hold of theresources of the Lord Omnipotent. THE PATHWAY OF LIFE. 281 We might turn a lot of to righteousness by Christian admonition. Do not waituntil you can make a formal speech. Address the one subsequent to you. Just one particular sen-tence may do the work, just 1 question, just one particular look. The formal speak that

Text Appearing Soon after Image:

THE VOICE OF PRAYER. starts wnth a sigh and ends with a canting snuffle is not what is wanted, but theheart-throb of a man in dead earnest. There is not a soul on earth that you maynot bring to God if you rightly go at it. They said Gibraltar could not be taken. 282 THE PATHWAY OF LIFE. It is a rock 1600 feet higher and three miles lengthy. But the English and Dutch didtake it. Artillery, and sappers and miners, and fleets pouring out volleys ofdeath, and thousands of males, reckless of danger, can do anything. The stoutest

Note About Photos

Please note that these photos are extracted from scanned web page photos that may have been digitally enhanced for readability – coloration and look of these illustrations might not perfectly resemble the original operate.