Some cool plastic machining organization photos:

Steven F. Udvar-Hazy Center: south hangar panorama, including Air France Concorde, Boeing 307 Stratoliner “Clipper Flying Cloud”, De Havilland-Canada DHC-1A Chipmunk Pennzoil Special, Monocoupe 110 Unique amongst other individuals

Image by Chris Devers

Quoting Smithsonian National Air and Space Museum | Monocoupe 110 Unique:

Air show pilot and aerobatic champion W. W. "Woody" Edmondson thrilled audiences with his Monocoupe 110 Particular all through the 1940s. Edmondson, who named the airplane Small Butch for its bulldog-like appearance, placed second to "Bevo" Howard and his Bücker Jungmeister in the 1946 and ’47 American Aerobatic Championships, but he won the 1st International Aerobatic Championship in 1948.

The Monocoupe 110 Special was a clipped-wing version of the 110, part of a line that began with Don Luscombe’s Mono 22 and continued with the 70, 90, and 110 models. The sport coupes of the 1930s, these quickly and maneuverable aircraft were excellent for racers Phoebe Omlie and Johnny Livingston. Ken Hyde of Warrenton, Virginia, restored Little Butch prior to its donation to the Smithsonian.

Gift of John J. McCulloch

Manufacturer:

Monocoupe Airplane Co.

Date:

1941

Nation of Origin:

United States of America

Dimensions:

Wingspan: 6.9 m (23 ft.)

Length: six.2 m (20 ft. 4 in.)

Height: two.1 m (six ft. 11 in.)

Weight, empty: 449 kg (991 lbs.)

Weight, gross: 730 kg (1,611 lbs.)

Top speed: 313 km/h (195 mph)

Engine: Warner 185, 200 hp

Supplies:

Fuselage: steel tube with fabric cover

Physical Description:

High-wing, 2-seat, 1940’s monoplane. Warner Super Scarab 185, 200hp engine. Red with white trim. Clipped wings.

• • • • •

Quoting Smithsonian National Air and Space Museum | De Havilland-Canada DHC-1A Chipmunk, Pennzoil Unique:

De Havilland originally developed the Chipmunk right after World War II as a primary trainer to replace the venerable Tiger Moth. Amongst the tens of thousands of pilots who educated in or flew the Chipmunk for pleasure was veteran aerobatic and movie pilot Art Scholl. He flew his Pennzoil Special at air shows throughout the 1970s and early ’80s, thrilling audiences with his ability and showmanship and proving that the design was a best-notch aerobatic aircraft.

Art Scholl purchased the DHC-1A in 1968. He modified it to a single-seat airplane with a shorter wingspan and larger vertical fin and rudder, and produced other modifications to improve its performance. Scholl was a 3-time member of the U.S. Aerobatic Team, an air racer, and a movie and tv stunt pilot. At air shows, he typically flew with his dog Aileron on his shoulder or taxied with him standing on the wing.

Present of the Estate of Arthur E. Scholl

Manufacturer:

De Havilland Canada Ltd.

Pilot:

Art Scholl

Date:

1946

Country of Origin:

United States of America

Dimensions:

Wingspan: 9.4 m (31 ft)

Length: 7.9 m (26 ft)

Height: 2.1 m (7 ft 1 in)

Weight, empty: 717 kg (1,583 lb)

Weight, gross: 906 kg (two,000 lb)

Best speed: 265 km/h (165 mph)

Engine: Lycoming GO-435, 260 hp

Supplies:

General: Aluminum Monocoque Physical Description:Single-engine monoplane. Lycoming GO-435, 260 hp engine.

• • • • •

Quoting Smithsonian National Air and Space Museum | Press Release: National Air and Space Museum Receives Boeing S-307 Stratoliner for Show at Steven F. Udvar-Hazy Center, the Museum’s New Companion Facility at Dulles Airport:

The Smithsonian’s National Air and Space Museum welcomed today (Aug. 6) the sole surviving Boeing S-307 Stratoliner to its new house when the silver pioneering airliner arrived at Washington Dulles International Airport in Virginia for show at the museum’s new Steven F. Udvar-Hazy Center. The museum’s companion facility, adjacent to the airport, opens to the public Dec. 15.

The luxuriously appointed Stratoliner, constructed in the late 1930s, was the world’s initial passenger airplane to be pressurized, enabling it to keep away from rough climate by flying at unprecedented altitudes (20,000 feet) for transports of the era.

The airplane has been in the museum’s collection because 1972 but due to the fact of its size and weight could not be displayed at the museum’s flagship creating on the National Mall. A team of volunteers and Boeing employees performed comprehensive restoration operate on the airplane in Seattle.

"Visitors to the Udvar-Hazy Center will take one particular look at this airplane and be transported back to a glamorous age when the planet became smaller for the traveler who required speed and luxury," stated Gen. J.R. "Jack" Dailey, director of the National Air and Space Museum. "We are indebted to the Boeing restoration group for turning back the clock on this lovely aircraft."

The Stratoliner arrived in Northern Virginia following an look at the Experimental Aircraft Association’s annual Fly-In at Oshkosh, Wisc. The airplane flew from Allegheny County Airport near Pittsburgh, exactly where it landed August 5th since of undesirable climate.

With a wingspan of 107 feet and a cabin almost 12 feet wide, the Clipper Flying Cloud will be exhibited at ground level in the Udvar-Hazy (pronounced OOD-var HAH-zee) Center aviation hangar.

[…]

The Clipper Flying Cloud was delivered to Pan American Airways with two other individuals in 1940. The aircraft carried 33 passengers and a crew of five. The Pan American Airways airplane was reconfigured to seat 45 passengers. Stratoliners included space for berths for overnight travel paneling in the cabin and lavatory wall fabric featuring the Pan Am logo, planet map and exotic animals and eight divans.

The Clipper Flying Cloud started service flying Caribbean routes for two years. In the course of World War II, it flew in South America under the path of the U.S. Army Air Forces. In 1946, it created every day runs between New York and Bermuda. Throughout the subsequent two decades it passed by means of the hands of several owners, and as soon as served as a presidential plane for the notorious Haitian leader "Papa Doc" Duvalier. Following its Haitian sojourn, the Clipper Flying Cloud landed in Arizona.

In 1969, a visiting National Air and Space Museum curator spotted the airplane in Arizona and quickly recognized its historic significance, even although its then-owner planned to convert it into a fire bomber. The Smithsonian subsequently acquired the aircraft and later made arrangements with the Boeing Company for the restoration, dubbed "Operation Flying Cloud," at the Seattle plant where the Stratoliner was originally constructed.

Boeing technicians and former Pan American staff voluntarily spent six years completely restoring the Stratoliner before it made an emergency landing in Elliott Bay in 2002. Considering that then, the restoration team has performed further work so that visitors to the Udvar-Hazy Center will have the opportunity to view the aircraft as it looked the day it rolled off the assembly line far more than 60 years ago.

• • • • •

Quoting Smithsonian National Air and Space Museum | Concorde, Fox Alpha, Air France:

The initial supersonic airliner to enter service, the Concorde flew thousands of passengers across the Atlantic at twice the speed of sound for more than 25 years. Developed and constructed by Aérospatiale of France and the British Aviation Corporation, the graceful Concorde was a gorgeous technological achievement that could not overcome significant financial difficulties.

In 1976 Air France and British Airways jointly inaugurated Concorde service to destinations about the globe. Carrying up to 100 passengers in excellent comfort, the Concorde catered to first class passengers for whom speed was vital. It could cross the Atlantic in fewer than four hours – half the time of a traditional jet airliner. Nevertheless its high operating charges resulted in very higher fares that limited the quantity of passengers who could afford to fly it. These difficulties and a shrinking industry at some point forced the reduction of service till all Concordes were retired in 2003.

In 1989, Air France signed a letter of agreement to donate a Concorde to the National Air and Space Museum upon the aircraft’s retirement. On June 12, 2003, Air France honored that agreement, donating Concorde F-BVFA to the Museum upon the completion of its last flight. This aircraft was the first Air France Concorde to open service to Rio de Janeiro, Washington, D.C., and New York and had flown 17,824 hours.

Gift of Air France.

Manufacturer:

Societe Nationale Industrielle Aerospatiale

British Aircraft Corporation

Dimensions:

Wingspan: 25.56 m (83 ft ten in)

Length: 61.66 m (202 ft 3 in)

Height: 11.3 m (37 ft 1 in)

Weight, empty: 79,265 kg (174,750 lb)

Weight, gross: 181,435 kg (400,000 lb)

Top speed: 2,179 km/h (1350 mph)

Engine: Four Rolls-Royce/SNECMA Olympus 593 Mk 602, 17,259 kg (38,050 lb) thrust each

Manufacturer: Société Nationale Industrielle Aérospatiale, Paris, France, and British Aircraft Corporation, London, United Kingdom

Physical Description:

Aircaft Serial Quantity: 205. Such as four (four) engines, bearing respectively the serial number: CBE066, CBE062, CBE086 and CBE085.

Also integrated, aircraft plaque: "AIR FRANCE Lorsque viendra le jour d’exposer Concorde dans un musee, la Smithsonian Institution a dores et deja choisi, pour le Musee de l’Air et de l’Espace de Washington, un appariel portant le couleurs d’Air France."

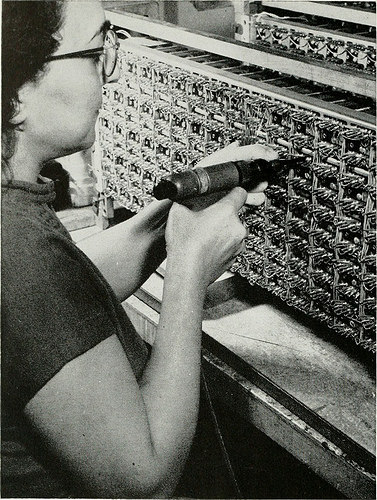

Image from page 471 of “Bell telephone magazine” (1922)

Image by World wide web Archive Book Images

Identifier: belltelephonevol3132mag00amerrich

Title: Bell telephone magazine

Year: 1922 (1920s)

Authors: American Telephone and Telegraph Company American Phone and Telegraph Company. Info Dept

Subjects: Telephone

Publisher: [New York, American Telephone and Telegraph Co., and so on.]

Contributing Library: Prelinger Library

Digitizing Sponsor: Net Archive

View Book Web page: Book Viewer

About This Book: Catalog Entry

View All Photos: All Images From Book

Click right here to view book on the web to see this illustration in context in a browseable on the internet version of this book.

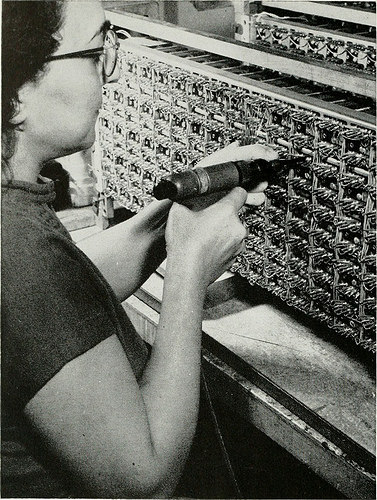

Text Appearing Before Image:

ayers of pitch, mica flakes,and anti-stick remedy. Then a farbetter kind, known as C was intro-duced, utilizing synthetic rubber as in-sulation and neoprene for the jacket.To produce the massive quantities ofdrop-wire essential. Western Electricengineers developed and set up one particular ofindustrys most efficient shops forprocessing synthetic rubber. Rawmaterials move by conveyor to bigmixers, where they are mixed andtimed automatically. The insulating and jacketing compounds move fromone step in the procedure to one more byoverhead conveyors, and lastly arewound in big coils beside the extrud-ing machines, exactly where the coverings areplaced on the copper-coated steelwires. Tests have indicated that Cs su-perior resistance to abrasion, sunlight,and basic climate situations addsup to a lifetime of numerous occasions thatof the TP variety. Maintenance andrepair fees are reduced drastically,phone users get more dependableservice, and the Bell Businesses dropwire charges go down. 174 Bell Phone Magazine AUTUMN

Text Appearing After Image:

^Shooting wire connections onto terminals eliminates pliers^ solderi)ig iron, solder, and numerous motions in yyiaking six hundred millioyi electrical connections a year in Western Electric factories Relays Get a New Appear Yet another old standby of telephony,the relay, has undergone changes inthe interests of reduced production andmaintenance charges and improved reli-ability. A relay is an electromagneticswitching device utilized in all centraloffices to connect the calling with thecalled telephone. Now a new design,named the wire spring relay, hasmade its look to challenge thestandard variety in use for numerous years. strategies. Gone are thenarrow strips of springmetal assembled in lay-ers around an electro-magnet which cause thecontact points to meetor separate and hence toclose or open circuits.In their place are springwires molded securelyinto a plastic block.Also eliminated is thearrangement of tinyparts, nuts, and boltsthat held the old-typerelay with each other. In-stead, a single U-shapedclamp is the

Note About Pictures

Please note that these photos are extracted from scanned web page images that may have been digitally enhanced for readability – coloration and appearance of these illustrations could not perfectly resemble the original work.

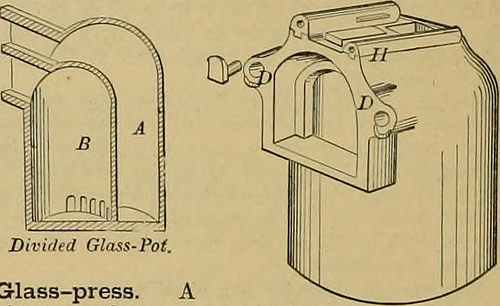

Image from page 53 of “Knight’s American mechanical dictionary : a description of tools, instruments, machines, processes and engineering, history of inventions, basic technological vocabulary and digest of mechanical appliances in science and the art

Image by Net Archive Book Photos

Identifier: knightsamericanm02knig

Title: Knight’s American mechanical dictionary : a description of tools, instruments, machines, processes and engineering, history of inventions, common technological vocabulary and digest of mechanical appliances in science and the arts

Year: 1882 (1880s)

Authors: Knight, Edward H. (Edward Henry), 1824-1883

Subjects: Industrial arts Mechanical engineering

Publisher: Boston : Houghton, Mifflin and Organization

Contributing Library: NCSU Libraries

Digitizing Sponsor: NCSU Libraries

View Book Page: Book Viewer

About This Book: Catalog Entry

View All Photos: All Photos From Book

Click here to view book on-line to see this illustration in context in a browseable on-line version of this book.

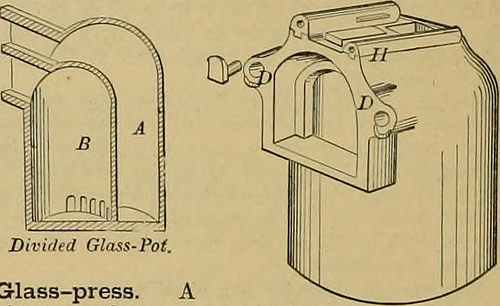

Text Appearing Prior to Image:

Gtnss-Fots. jf the charge. lig. 2248. Fig. 2249.

Text Appearing After Image:

Glass-press. A device to apply press- Newmans Glass-Pot. ure to glass in a mold although in a plastic state. In the press shown, theplunger is hung on a sliding head moving u|)on guidesand operated by connection with a rock-shaft. Thecover of the mold is helil down by followeis, and themold slipped in and out at the requisite jieriods.Power is ajiplied by a lever, which is counterpoisedby a weight. Glass-roUing. About 1849, Bessemer obtaineda ])atent iu England for a process of rolli)]g gla.s.s, tomake ]ilate-gla.ss and stay away from the undulating surfaceincident to blown window-glass. Messrs. Possibility, of Binninghani, expended .£100,-000 in attempting to ]ierfect the machinery therefor, butfailed to acconqilish it, and abandoned the eiiter-jirise. The glass, in its pasty condition, was passedfrom a hopper in between two Iollers on horizontala.es and was Icceiveil on a flaltening-table. Glass-silver-ing. Glass for mirrors or orna-mentatiim is sihered by one ol two approaches thefirst is merely factitio

Note About Pictures

Please note that these images are extracted from scanned web page pictures that may have been digitally enhanced for readability – coloration and look of these illustrations might not perfectly resemble the original function.